Only company in the world to have succesfully completed the full automation of a Lausmann type malting plant.

Full automation of a Lausmann (horizontal) malting plant including:

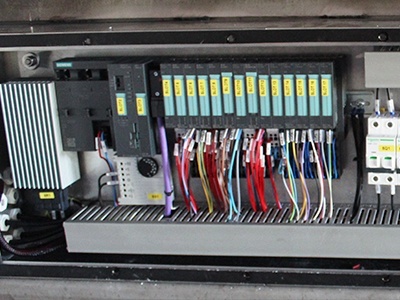

- Siemens S5 to PCS7 migration.

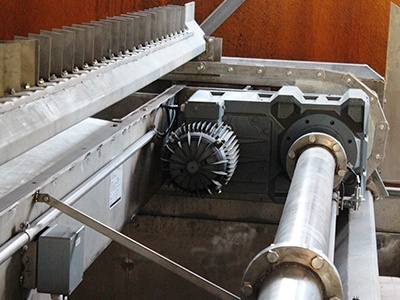

- Fully autonomous turner machine with auto-positioning.

- Fully automated transfer of green malt during the entire process.

- Automatic system to even out malt, layer height is also selectable.

- Additional safety features installed in the turner for auto-mode.

- Additional safety features installed to protect beams, spindlers & structures.

- Green malt transfer system integrated within the plant process.

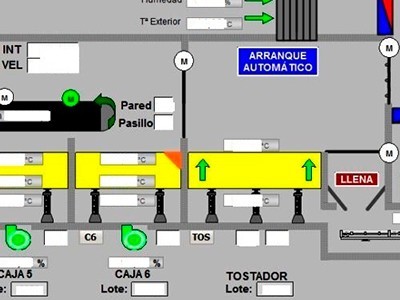

- Recipes are fully configurable and can be selected from workstations by an authorized operator.

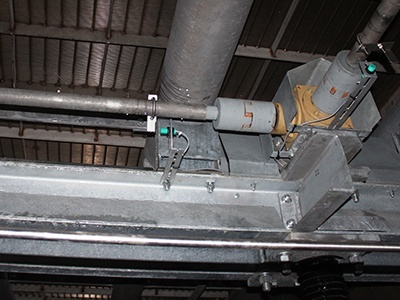

- Automatic water spray.

- Automatic high pressure cleaning for boxes, walls and ceiling.

- Steeping, germination and kilning process optimization with remarkable reduction in power consumption.

A few images of the process:

Main references

INTERMALTA Navarra (Spain)

MALTIBÉRICA (Portugal)

The integrated engineering works carried out at these facilities have consisted of:

- Detailed engineering.

- Full automation of the malting plant (Lausmann type) with PCS7, successfully achieving autonomous operation of the system (with no human intervention) including high pressure cleaning.

- Process optimization (Steeping, germination and kilning).

- Complete development of electrical installation (engineering, electrical enclosures, assembly, programming and commissioning) of silo plant (barley and malt) and water treatment plant.

INTERMALTA Seville (Spain)

Power distribution center.

Barley silos, malt silos, pumps and high pressure cleaning, steeping, germination, kilning, cooling and water treatment plant.

The integrated engineering works carried out at these facilities have consisted of:

- Complete development of electrical installation (engineering, electrical enclosures, assembly, programming and commissioning).

- Full automation of the factory with PCS7 and redundant systems.

INTERMALTA Albacete (Spain)

- PCS7 migration of all systems with no production interruption, including barley and malt silos, steeping, germination, kilning, cooling and water treatment plant.

THE SWAEN Kloosterzande (Netherlands)

- Complete development of electrical installation (engineering, electrical enclosures, assembly, programming and commissioning) of a new horizontal production line for special malts.

- S7-400 & Proleit Automation.

FAMOSA Santa Cruz de la Sierra (Bolivia)

- Engineering, electrical enclosures assembly and commissioning of a wheat storage and transport system.

- S7-400 & WinCC Automation.

TALLERES LANDALUCE

- Filter installation in brewhouse. Sobebra, Parakou (Benin).

- Filter installation in brewhouse. Sobraga, Port Gentil (Gabon).

MALTEUROP Langerringen (Germany)

- S5 to S7 migration in water treatment plant. Several software modifications in PCS7 & remote support.